Ceramic porous agent

- Categories:Application (powder)

- Time of issue:2018-02-27 00:00:00

- Views:0

Microporous ceramic porous agent

Polymethyl methacrylate micronized powder (PMMA) is a new type of functional additive, which has the appearance of a white powder with excellent dispersion and a perfectly round spherical microscopic shape. In the range of 1 to 20 microns, different particle sizes and uniformity are available upon request.

For the application research of this application of porous agent, we also commissioned the Shanghai Institute of Silicate, Chinese Academy of Sciences to do the corresponding experimental analysis of PMMA micro powder, they gave us the conclusion of the report is the ideal additive for the preparation of porous ceramics, the following quoted the relevant test data provided to us by the unit.

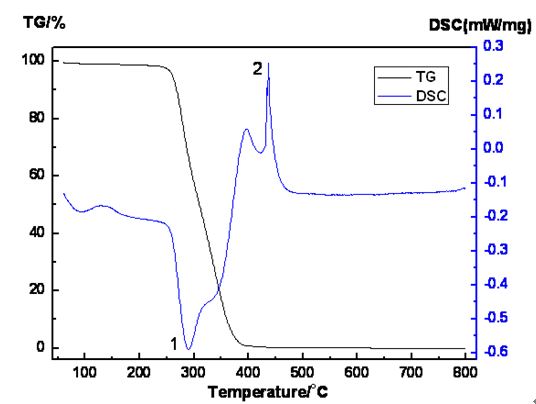

1、Thermal analysis

The test used the STA429 thermal analyzer made by Netzsch, Germany, to analyze the thermal stability of PMMA powder using the differential heat-thermogravimetric method. The temperature increase rate was 10 oC/min and the working atmosphere was air. According to the differential thermal analysis curve of PMMA (Figure 1), it is obvious that the PMMA powder loses very little weight (<2%) before 240oC and has a small heat absorption peak at about 100oC, which can be considered to be caused by the heat absorption of water volatilization; the powder loses significant weight between 240oC and 400oC and has an obvious heat absorption peak at about 300oC as shown in Figure 1 1, so it can be considered that the decomposition of PMMA powder between 240oC and 400oC is basically completed; the powder at about 450oC produces an obvious exothermic peak shown in Figure 1, 2, is due to the heat released by the combustion of the gas generated by the decomposition of PMMA, up to this PMMA powder has been completely exhausted, with the further increase in temperature, there is no weight loss, heat absorption or exothermic phenomenon.

Figure 1. Differential heat-thermogravimetric analysis of PMMA micronized powder produced by synthesis chemical students

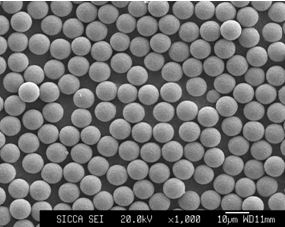

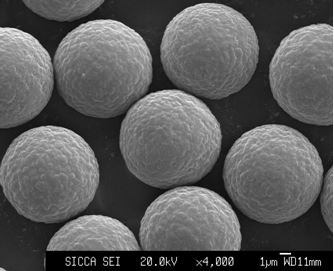

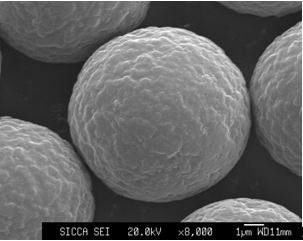

2. Microscopic analysis

The testers of this unit also applied scanning electron microscopy (SEM, JSM-6700F, JEOL, Japan) analysis to observe the morphology. As shown in Figure 2.

|

|

|

|

(a) |

(b) |

(c) |

Figure 2 SEM morphology of PMMA micropowder (a) ×1000 (b) ×4000 (c) ×8000

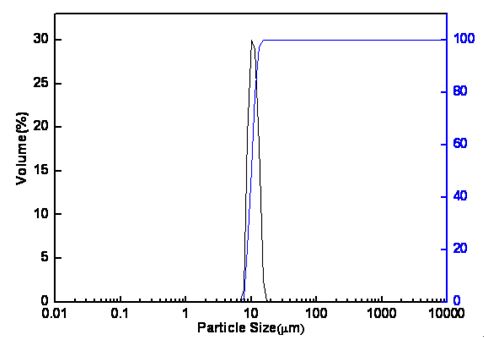

3、Particle size analysis

The particle size analysis of PMMA micro powder prepared by Synthetic Chemical is shown in Figure 3, from which it can be seen that the particle size distribution of the powder is narrow and normally distributed.

Figure 3 Particle size distribution of PMMA powder

4. Conclusion

a.) PMMA micronized powder decomposes between 240oC and 400oC and is completely excluded before 500oC.

b.) PMMA micropowder shows regular round spherical shape in microscopic, which is suitable for the formation of gas phase space in porous materials.

Taken together, the PMMA micropowder prepared by Synthetic Chemical (Suzhou) is an ideal porogenic agent and will have a wide application prospect in the field of porous ceramic preparation.

Recommended products for porosity agents

|

Species name |

Dispersion type |

Appearance |

Cross-linking state |

Average particle size (μm) |

Heating reduction(%) |

Gel fraction(%) |

|

MX-300 |

Monodisperse |

White micro powder |

High crosslinking |

3 Around |

Below 2.0 |

-- |

|

KMR-3TA |

Polydispersed |

White micro powder |

High crosslinking |

3 Around |

Below 2.0 |

-- |

|

MX-500 |

Monodisperse |

White micro powder |

High crosslinking |

5 Around |

Below 2.0 |

97.0 or above |

|

MX-1000 |

Monodisperse |

White micro powder |

High crosslinking |

10 Around |

Below 2.0 |

97.0 or above |

|

MX-1500H |

Monodisperse |

White micro powder |

High crosslinking |

15 Around |

Below 2.0 |

97.0 or above |

Scan the QR code to read on your phone

CONTACT INFORMATION

ADD:No. 271 Xinglong Street, Suzhou Industrial Park

E-MAIL:suntengjiao@soken-sz.com

TEL:0512-62832891

FAX:0512-62831029